Several factors are contributing to the downturn.

Others are reading now

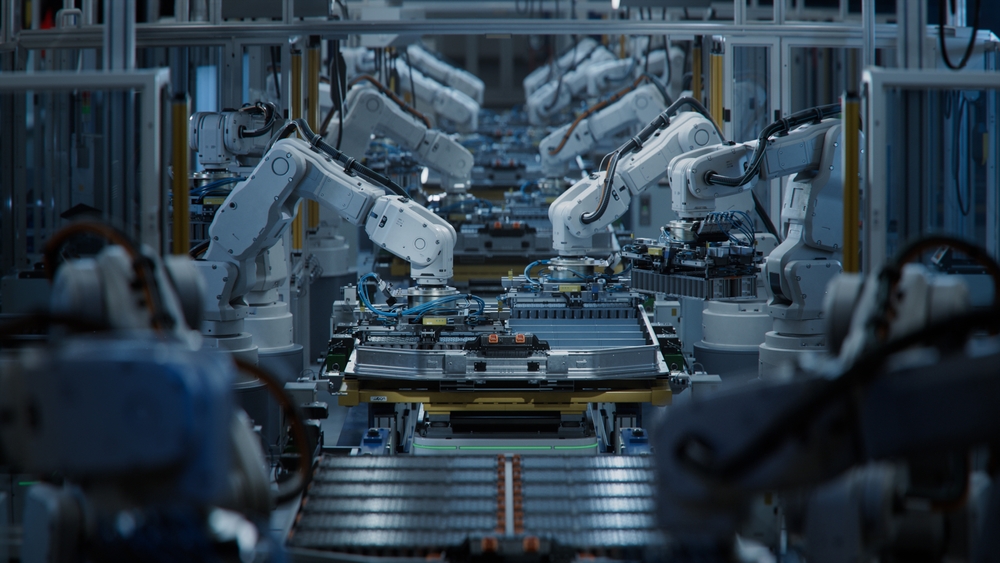

The UK car industry, once a major player in global manufacturing, is facing one of its toughest periods in recent history.

Amid economic uncertainty and shifting consumer preferences, car production has plummeted to levels not seen in decades, highlighting the significant challenges facing the sector.

In November 2024, just 64,216 cars were produced in the UK, marking the lowest monthly output since November 1980, according to Boosted.

Also read

Brexit Complicates Matters

According to data from the Society of Motor Manufacturers and Traders (SMMT), this represents a sharp 30.1% drop from the same month last year.

A total of 27,711 fewer vehicles rolled off assembly lines, marking the ninth consecutive month of declining production.

Several factors are contributing to the downturn. Industry experts point to strategic product decisions, global market instability, and lingering logistical issues as key drivers.

Last year’s production figures were inflated by a recovery from supply chain disruptions caused by the COVID-19 pandemic, making this year’s decline even more pronounced.

The shift toward electric vehicles (EVs) has added pressure on automakers. The UK’s commitment to phasing out petrol and diesel car sales by 2035 has forced manufacturers to rethink their production strategies.

This transition, combined with a global economic slowdown, has weakened consumer demand for both new and used cars.

Microchip shortages, a persistent issue since the pandemic, continue to hinder production.

The industry had hoped for improvements, but the prolonged impact of these shortages has caught many manufacturers by surprise.

Brexit has further complicated matters, introducing higher costs and logistical challenges for exporting vehicles.

Exports accounted for 78% of the UK’s car production in November, a slightly higher share than usual. However, the overall reduced output diminishes the significance of this figure.

Looking ahead, the UK car industry faces an uphill battle. Automakers such as Ford have warned that government support will be essential for navigating the transition to EVs. Without it, thousands of jobs could be at risk.